Treatment for an Antibiotic Industry Effluent

The wastewater generated from an Antibiotic Industry is acidic in nature having COD around 2,20,000 ppm and BOD around 70,000 ppm. Prakruti’s R&D team develop a process based on Biological Treatment, to achieve the final disposal norms to CETP of COD less than 2000 ppm.

Treatment for Dye Manufacturing Industry Effluent

Prakruti’s R&D team developed Dye recovery system using Membrane Technology. The coloured effluent streams after dye recovery is Biologically Treated using Anaerobic treatment followed by Membrane Bioreactor (MBR) Technology for RO feed Water Recovery.

Treatment for an Animal Feed Manufacturing Industry Wastewater

Effluent stream from Animal Feed Manufacturing plant contain high Dissolved Organic load that is difficult to treat. Industry incinerates this effluent stream to achieve zero discharge.

Prakruti’s R&D team develop a process based on Biological Treatment, that yield treated effluent conforming to on land gardening disposal norms.

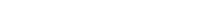

Treatment for Cyanide bearing Wastewater

Prakruti’s R&D team optimized a techno-economical treatment for Cyanide bearing effluent streams, that completely dissociates cyanide and organic content. No traces of cyanide encountered in resultant sludge. The process excludes use of Chlorine and its compounds for treatment.

Treatment for Pharmaceutical Industry Wastewater

Wastewater from Pharma units contain high Dissolved Organic matter that belong to mercaptane family. Prakruti’s R&D team developed Substrate specific microbial consortia to degrade such pollutants. The treated effluent conforms to the CETP disposal norms of COD less than 2000 pm. Such wastewater otherwise had to be incinerated!!

Treatment for Electroplating Wastewater

Prakruti’s R&D team has optimized a techno-economical treatment for metal bearing wastewater streams. The resultant sludge after treatment contains non leachable heavy metals. The treated effluent is recovered for reuse.

Treatment for Gelatin Waste

Soft Gelatine capsule manufacturers generated considerable quantum of gelatine net that is wasted. This waste contains microbial inhibitors and hence is difficult to degrade. Prakruti’s R&D team has developed substrate specific microbial consortia that reproduce on this waste material thus degrading it and also reduces the volume. The end product of the treatment can be used for Protease Manufacturing.

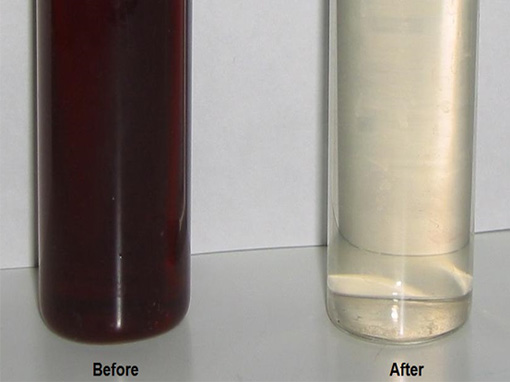

Treatment for Textile Water Jet Loom Industry Wastewater

In water jet loom textile sector, considerable quantity of water is wasted as it contains turbidity. Prakruti’s R&D team has developed a process based on Membrane Technology, for the removal of impurities and recover water for reuse. The process involves no use of chemicals!!!

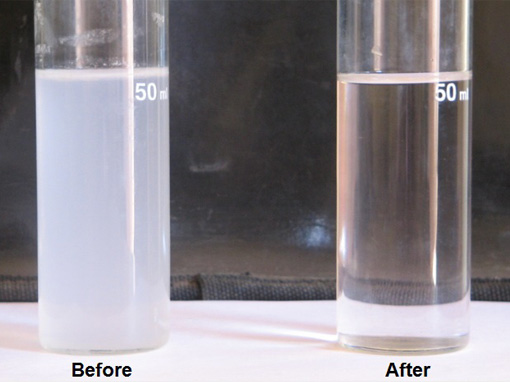

Treatment for Textile Dyeing Industry Wastewater

In textile dyeing sector, considerable quantity of water is wasted as it contains colour, COD and turbidity. Prakruti’s R&D team has developed a process based on Membrane Technology, for the removal of impurities and recover water for reuse. Partial Result of one such full scale installation at Dhaka, Bangladesh is shown below.

Treatment for Synthetic Organic Chemical Industry Wastewater

Wastewaters from Synthetic Organic Chemical units are multi product plants with less effluent quantity but contain complex dissolved organic matter those are not easily biodegradbale. Prakruti’s R&D team developed AOP treatment to degrade such pollutants. The treated effluent conforms to the CETP disposal norms of COD less than 2000 pm.

Treatment for Plating Industry Wastewater

Wastewaters from Plating units contain Cyanide and Hexavalent Chromium; which if treated conventional poses risk of formation of poisonous gas. Prakruti’s R&D team developed a specific treatment process to degrade such pollutants into its basic forms which can then be precipitated as hydroxides. The treated effluent conforms to the disposal norms.

Treatment for Agrochemical Industry Wastewater

Wastewaters from Agrochemical units contain high Ammonical Nitrogen, dissolved organic matter and phenolic compounds. Prakruti’s R&D team developed a specific treatment process to degrade such pollutants into its basic forms. The treated effluent conforms to the disposal norms.