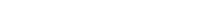

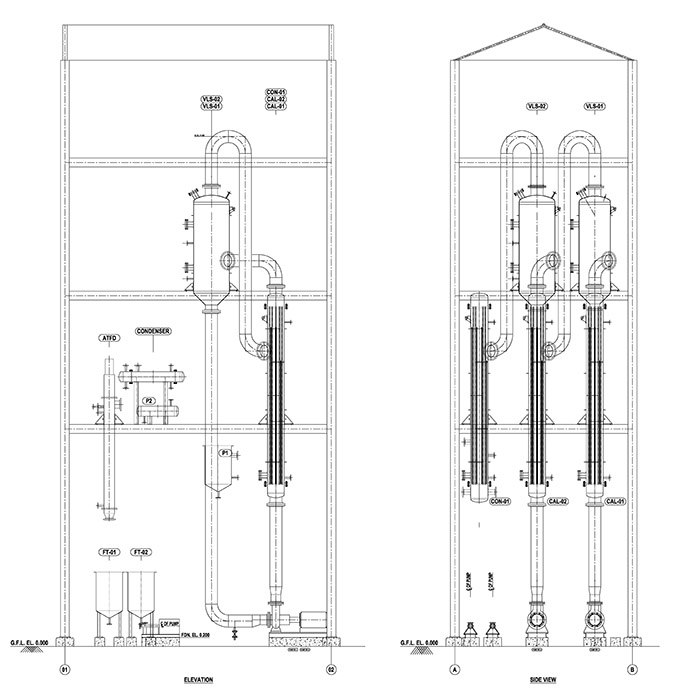

Thin Film Dryer is used to dry and collect baggable solids from high TDS solution that comes out of Multi Effect Evaporator after water recovery.

A typical Thin Film Evaporator consists of a tubular heat transfer area with an external heating jacket and a fast-revolving, inner rotor with flexible or rigid wiper elements. The feed product is evenly distributed by the rotor and its wipers over the heating surface, forming a thin liquid film of uniform thickness. This assures excellent heat transfer combined with constant renewal of the product film and provides an even heating and short residence time of the product.